My boys and I are participating in the 2011 Central Florida Scout Show on April 30th at UCF Stadium.

If you live in Central Florida, you've likely seen the billboards, or bought fundraiser discount cards from a Cub or Boy Scout.

My boys & I are running the booth for Cub Scout Pack 6 - the booths are intended to show Scouts and local visitors about the Scouting experience. I'm a big believer in the educational side of Scouting, and love that they have science and engineering in the program very early. With that in mind, our Scout Show booth will be all about GEARS! To make it appealing for this age group, we will be teaching about gears using LEGO GEARS and LEGO ROBOTS!

I'll use this blog post for updates since the show is a week away and we are now in execution mode.

Yesterday, we used some family time to create a 3-speed transmission with a clutch using the Lego NXT set. We used the plans and code from nxtprograms.com - if you have a Lego NXT robot, you MUST check out this site - we've had many awesome building sessions with their plans.

Here are some pics of my older son building the transmission with his grandfather & me. We used our normal system - I stage parts by section number, he builds. I generally only get to build if he gets really stuck - he takes great pride in being the Lego Master of the house...

More soon...

THIS BLOG HAS MOVED. PLEASE UPDATE ANY BOOKMARKS TO GO DIRECTLY TO WWW.RAISINGGEEKS.COM

Monday, April 25, 2011

Thursday, April 21, 2011

A nice little diversion...

Just when I thought I had my spring projects planed out, I met a group of local "maker" types at a group called FAMiLab. The people at FAMiLab run the geek spectrum from "makers" to networking guys, artists, etc. I went to meet them a few weeks ago since they have a reprap and while I was there, they were discussing the Great Global Hackerspace Challenge (GGHC) sponsored by element14. I'm not a huge fan of the term "Hackerspace" since the general public still thinks that "hacking" is an illegal act, but the wikipedia definition for Hackerspace captures the right spirit:

A hackerspace or hackspace (also referred to as a hacklab, makerspace or creative space) is a location where people with common interests, usually in computers, technology, science or digital or electronic art can meet, socialise and/or collaborate. A hackerspace can be viewed as an open community labs incorporating elements of machine shops, workshops and/or studios where hackers can come together to share resources and knowledge to build and make things.

I started brainstorming with the FAMiLab group one night on their project for the GGHC, and well, now I'm part of the team.

There are ~30 worldwide hackerspaces entering projects. The primary requirements for the project are:

A hackerspace or hackspace (also referred to as a hacklab, makerspace or creative space) is a location where people with common interests, usually in computers, technology, science or digital or electronic art can meet, socialise and/or collaborate. A hackerspace can be viewed as an open community labs incorporating elements of machine shops, workshops and/or studios where hackers can come together to share resources and knowledge to build and make things.

I started brainstorming with the FAMiLab group one night on their project for the GGHC, and well, now I'm part of the team.

There are ~30 worldwide hackerspaces entering projects. The primary requirements for the project are:

- Supports education

- Uses a microcontroller

- Uses a portable power source

There are some other judging criteria that include:

- Reproducibility

- Cost of the design

- Documentation

- Creativity

Three semi-finalists will be closen the week of May 2nd, and then these three semi-finalists get to present their device to a panel of celebrity judges at...Maker Faire :)

Rather than explain what it is here, check out the new website (its a work-in-progress) at www.sensingplatform.org.

We also now have a git repo, and some slideware here.

We also now have a git repo, and some slideware here.

I'll use the space below to capture some of the things I've learned on this project:

1) Writing Arduino Libraries

1) Writing Arduino Libraries

- This seems very simple, but it will test your C++ skills. Specifically the Wire library uses callbacks, and doing the callbacks into member functions of my library class...ug.

- #includes - they don't work in libraries in the Arduino build environment. Why is beyond me, but they don't work. Your end sketch must have your library includes AND any includes that your library needs as well.

- Your library code must be in ../[arduino-ide-folder]/libraries to be compiled and included. This makes working using a source repository like git a little more complicated. I used windows symlinks to create a folder under libraries that pointed to my rep library folder.

2) Git - I know about version control, but rarely work on software with others. It is pretty awesome to be able to work on shared source without having to email and play the "did you make changes" game.

3) ...more to come

Sunday, April 17, 2011

April 17th: Indy Racing Experience

My family gave me the Indy Racing Experience for Christmas... I scheduled it for this weekend hoping for nice weather, and it was VERY nice.

The whole family went along, and they let the boys right by the car as I was getting strapped in...

|

| All suited up! |

|

| Sure looks fast... |

|

| Posing for the picture that you KNOW you are going to buy at the end of your "experience"... |

|

| The sun was in their eyes - they were excited... |

|

| "Is now a good time to tell you I need to go to the bathroom?" :) |

|

| On my extra lap - apparently the instructor didn't see the checkered flag, so we took one more spin... |

|

| Done soooo soon... |

So in the end, it was a LOT of fun. Very exciting even at only 135 mph max speed. I averaged a little over 105 for all my laps - you follow the instructor and he slows down if you get too close - and I did a few times :)

I was a little disappointed to hear that its a motorcycle engine, not a de-tuned INDY motor. The biggest surprise was NO SHIFTING. They were breaking clutches too often, so they start you in 5th gear and give you a push... Oh well...at least I didn't have to worry about screwing up the gear...

It was an awesome present, I'm a very lucky man :)

Sunday, April 10, 2011

April 10th: MakerGear Prusa Mendel Kit - Build Day #3

I bounced around today, working on things as I figured out what parts went where. I'm sure it took much more time than it needed to, but it was fun anyway.

Remaining work:

1) Servo wiring

2) Hot End build & wiring

3) Heated Print bed thermistor install

4) RAMPS mounting

5) Power supply setup & connections

6) Use the green high-temp wiring for the heated build platform. Oops.

7) Pull the $#*$ X-idler and put in the rear fine adjustment screw I missed.

http://groups.google.com/group/makergear/browse_thread/thread/d8c926dc96f6b98d?pli=1

Today's work was on 4 major subsystems:

1) RAMPS electronics

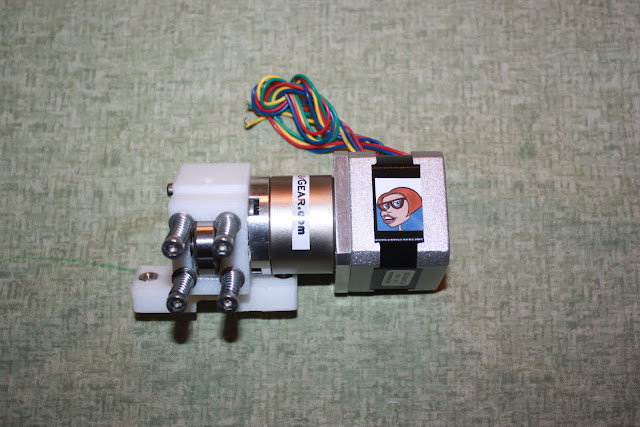

2) MakerGear Stepper Plastruder

3) EndStops

4) Heated Build Platform

Remaining work:

1) Servo wiring

2) Hot End build & wiring

3) Heated Print bed thermistor install

4) RAMPS mounting

5) Power supply setup & connections

6) Use the green high-temp wiring for the heated build platform. Oops.

7) Pull the $#*$ X-idler and put in the rear fine adjustment screw I missed.

Tons of pics below, with brain-dumps in the comments for now. I need to help improve the community documentation soon, these brain-dumps will help.

RAMPS - I started the RAMPS build a few weeks ago. Someone else was taking pics, so I don't have the beginning shots...

|

| This is where I'd stopped a few weeks ago... |

|

| Soldering the Pololu drivers - no, I wasn't following the instructions here, I had other things to finish on the RAMPS board, but I figured this was some easy soldering to get out of the way... |

|

| Another Pololu... |

|

| Look |

|

| Added the caps... |

|

| Adding the MOSFETs |

|

| Adding the fuse. I DID NOT install the optional diode. |

|

| Add caption |

|

| I pulled the jumpers & did lots of continuity testing looking for bad soldering... |

|

| Installed on the MEGA... |

|

| The MakerGear RAMPS kit (the 3 1k resistors are for the endstops, oops) |

|

| Fully populated RAMPS and a bare RAMPS board... |

|

| Adding the heatsinks provided by MakerGear |

|

| Yes, I did debate heatsink orientation with myself for a minute or two... |

|

| All heatsinks installed... |

MakerGear Stepper Plastruder

|

| My stepper extruder motor was backordered, thats why it isn't shown here. Luckily someone VERY COOL loaned me one until mine gets here... |

|

| Example of the print quality for some of the RP parts. Not great, but should be functional. Gives me something to print later... |

|

| I guessed on this part... |

|

| Hope this is right :) |

|

| Once I built it to this part, I had a MUCH better understanding of how it worked. I was so used to seeing WADE'S extruders, I couldn't quite figure out what was happening in the pics... |

|

Endstops - this was a bit of a puzzle figuring out what went where...by using the pics and pestering MG|Rick, I think i've got it...yesterday's build pics show the locations of the RP parts on the printer, these are mostly closeups of the mounting / wiring...

http://groups.google.com/group/makergear/browse_thread/thread/d8c926dc96f6b98d?pli=1

|

| I used shrink-tubing and the heat gun to clean up the connections... |

|

| I will use approx 2.3 million wireties before this thing is done. I tend to be obsessive with wire routing - too much time running wire with my buddy Lou who likes the wires nice & tidy :) |

Heated Build Platform - this took some time. I REALLY should have traced the holes for the platform before I built the Y-Carriage. Oh well.

|

| I'll switch to the nylon locking nuts later... |

|

| Always good to make polarity OBVIOUS |

|

| Remove the tape covering over the solder pads |

|

| My FIRST surface-mount soldering! |

|

| Those LEDs were NOT easy to hold in place while soldering! |

|

| I went with the suggested plan of an LED that lights with either polarity. I think I'll swap out the reverse polarity LED later with a RED one, but its good for now... |

|

| [Replace image once the high-temp green wire is used] |

|

| [Replace image once the high-temp green wire is used] |

|

| [Replace image once the high-temp green wire is used] |

|

| Shrink tubing is good. A little red electrical tape indicating the positive wire can't hurt either :) [Replace image once the high-temp green wire is used] |

|

| I used two sizes of shrink tubing to make a nice jacket for the connector. [Replace image once the high-temp green wire is used] |

|

| [Replace image once the high-temp green wire is used] |

|

| A quick bench test - the heated print bed pulling approx 10A at 12v. It warmed up quickly. I didn't get out the temp probe, I just let it get too hot to touch and unplugged it... |

Labels:

3D printer,

3d printing,

Arduino,

makergear,

mendel,

phineas,

prusa,

reprap

Subscribe to:

Comments (Atom)